COVID-19 has pushed antimicrobial coatings into the spotlight. However, surfaces treated with these coatings are not necessarily antiviral and effective against the COVID-19 virus. Antimicrobial coatings inhibit microorganisms, while antiviral coatings are agents that kill viruses or suppress their ability to multiply and spread. Other solutions like photocatalytic coatings have also been shown to be effective against bacteria and viruses. When considering the wide range of solutions used as preventive measures against COVID-19, it is important to understand the limitations of these technologies.

In this blog, we list and break down antimicrobial coating and additive technologies, detail the major challenges that these technologies face in relation to COVID-19, and delve into future market opportunities.

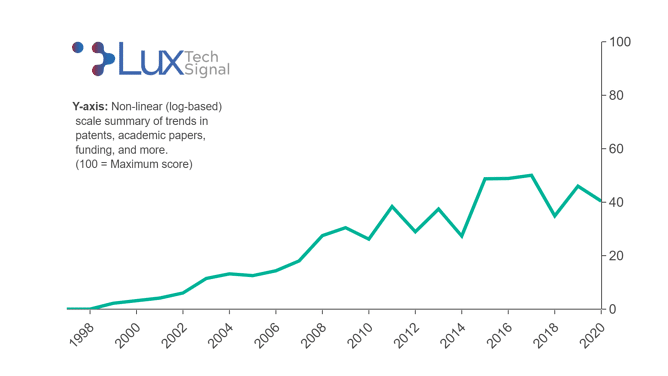

Figure 1. Antimicrobial Coatings Lux Tech Signal

Pre-COVID-19, antimicrobial coatings had a tough time finding widespread adoption, as their value and impact on human health have been difficult to demonstrate and quantify. COVID-19, however, has drastically changed the perception of antimicrobials as many look at these technologies as a much-needed safety measure. As shown in Figure 1, we are already seeing how COVID-19 has driven substantial interest in antimicrobial coatings this year, as the 2020 signal is keeping up with the steady trend of the decade. By the end of the year, we expect the Lux Tech Signal to spike and even double, as COVID-19 is proving to be a catalyst for antimicrobial research and funding.

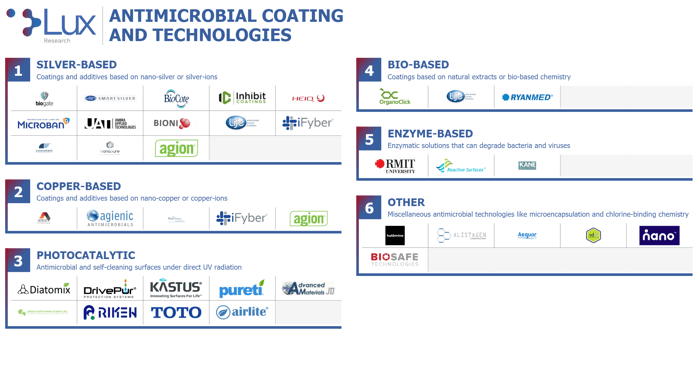

Figure 2: Antimicrobial Coating and Technologies Market Map

Technologies:

Figure 2 lists companies and startups that are working on various antimicrobial and photocatalytic technologies.

- Silver and copper: Metallic antimicrobial agents like silver and copper have been shown to be effective against both bacteria and viruses, as they release ions that damage cell membranes, inactivate proteins, and degrade DNA, resulting in the cell’s death. While there is ample literature detailing these effects, ensuring that these metallic antimicrobial agents are equally effective when dispersed in coating matrices is another challenge. There are a number of metallic antimicrobial coatings and additives available on the market; not all of these solutions claim to be effective against COVID-19. Developers have various formulations and loadings of metallic agents, and testing must be done to understand their efficacy. While useful as a passive cleaner, these metallic antimicrobial coatings commonly underperform commercially available cleaners in terms of bacteria removal.

- Photocatalytic technology: Photocatalytic coatings use nano-titanium dioxide (TiO2), which absorbs UV light and produces reactive hydroxyl radicals that break down organic compounds and pollutants on its surface. This technology is considered a light-activated antimicrobial and has been used for its self-cleaning functionality as well as its air cleaning qualities. Most photocatalytic coating developers target the elimination of pollution and smog; however, there is an opportunity to prevent the spread of bacteria and viruses if used properly. Photocatalytic technologies require UV light, which is generally limited to outdoor applications; however, some startups, such as PureTi and Kastus, are developing technologies that are active with indoor visible light or special UV-A indoor lighting systems.

- Antimicrobial enzymes: Some enzyme-based coatings mimic the behavior of photocatalytic coatings by producing reactive oxygen species that kill bacteria under light; this could be used to produce longer-lasting antimicrobial coatings. While enzyme-based antimicrobials are already commercialized in food applications, they are much less mature in paint and coating applications. Cost and scalability is an issue today; however, enzyme-based antimicrobials are promising, as synthetic biology could make these novel biocides scalable.

- Bio-based antimicrobial technology: Several companies are relying on natural extracts and bio-based solutions to impart antimicrobial properties. A majority of bio-based antimicrobial technologies are within the food packaging space, using polysaccharides or chitosan with inherent antimicrobial or antifungal properties. There are also a number of applications within healthcare, such as Ryan Nano Medicine‘s protein-based antimicrobial coatings made from natural plants.

- Other: There are other methods of maintaining antimicrobial properties on surfaces, including microencapsulation of antimicrobial agents and disinfectant stabilization technologies like Alistagen‘s and Nano‘s, respectively. Other companies like Bio-Fence and Halomine develop technologies that prolong the use of traditional chlorine-based disinfectants using chlorine-binding polymers.

Challenges:

- Efficacy and durability: Antimicrobial coatings often struggle to prove that their incorporation leads to better health outcomes – a point that is critical to their value proposition. We are skeptical about current antiviral and antimicrobial solutions for COVID-19 due to a lack of certainty and documentation around performance. Furthermore, there are still questions over antimicrobial effectiveness, the durability of the coating, and FDA/regulatory approval. Companies like HeiQ that have made antiviral claims must undergo further testing and validation to warrant these claims. Most antimicrobial coatings have a reapplication timeline of several years; however, some companies have shortened that frequency timeline to 60 or 90 days to ensure effectiveness against COVID-19. If there is concern of early wearing due to use or environmental conditions, continuous monitoring or testing may be warranted to ensure efficacy. There are other concerns for photocatalytic coatings, as their catalytic additives may break down the matrix they’re embedded in, facing both durability and health concerns.

- Regulatory: A large challenge with new antimicrobial technologies in the next few months will be regulatory approval, as new disinfectant and antimicrobial solutions must have EPA and FDA approval to make claims. Gaining regulatory approval takes years, and given the urgency of the situation, some materials and coating developers have decided to forgo claims altogether, urging potential users to test their coatings for antimicrobial or antiviral effects. However, gaining regulatory approval will drive stronger adoption, as the approval sheds light on the health effects, boosting consumer awareness and acceptance.

- Health and environmental concerns: With the increased adoption of antimicrobial and antiviral coatings, there may be increased concerns of bacterial and viral resistance, which may go unchecked due to the lack of regulation. Within photocatalytic coatings, there is a concern that these coatings break down organic materials indiscriminately (including the matrix that they sit on), which can generate free radicals on or near the body, potentially causing negative long-term health effects. Furthermore, with mass adoption of these coatings for surfaces and buildings, there may be increased leaching of these compounds (including silver and TiO2) into the environment and waterways

Opportunities and Outlook:

Driven by COVID-19, Lux expects major growth of antimicrobial coatings within the transportation and medical industry as well as deployment in public spaces. Already, we are seeing high interest in and early adoption of these technologies, including by the Prague Public Transit Company (DPP) and Hong Kong International Airport, which have responded to COVID-19 through the adoption of antimicrobial technologies on train cars and at flight arrivals. Previously, Lux discussed emerging antimicrobial coating opportunities within apparel, healthcare, food, and packaging applications, which we expect to surge in the next two years.

From touch screens to ride-sharing fleets, antimicrobial technologies will find long-term adoption from OEMs and CPGs. Companies can expect antimicrobial coatings to be commonplace for the foreseeable future, especially in high-traffic applications like transportation and healthcare.

COVID-19 has fundamentally changed our behavior, instilling a high level of precaution and changing our perspective on what is “clean.” The presence of antimicrobial coatings in these shared spaces can put a large majority of consumers more at ease even after COVID-19. While COVID-19 has changed the demand and driver for antimicrobial coatings, the landscape and material development of these technologies will remain the same for several years. Given the urgency of the situation, those within the materials and coatings industry should evaluate mature startups with existing antimicrobial and antiviral technologies, as material development is still resource- and time-intensive. The ability to deploy systems now is critical, as we expect to see major rollout of antimicrobial coatings and disinfectant/decontamination systems and products in the next two years. Ultimately, when social distancing is relaxed, both consumers and industries will value the sense of safety and ease that comes with antimicrobial coatings in common spaces.